Attaining Superior Do With In-Mold Decorations in Manufacturing

Attaining Superior Do With In-Mold Decorations in Manufacturing

Blog Article

Grasping In-Mold Decorations: Techniques, Trends, and Ideal Practices for Ideal Outcomes

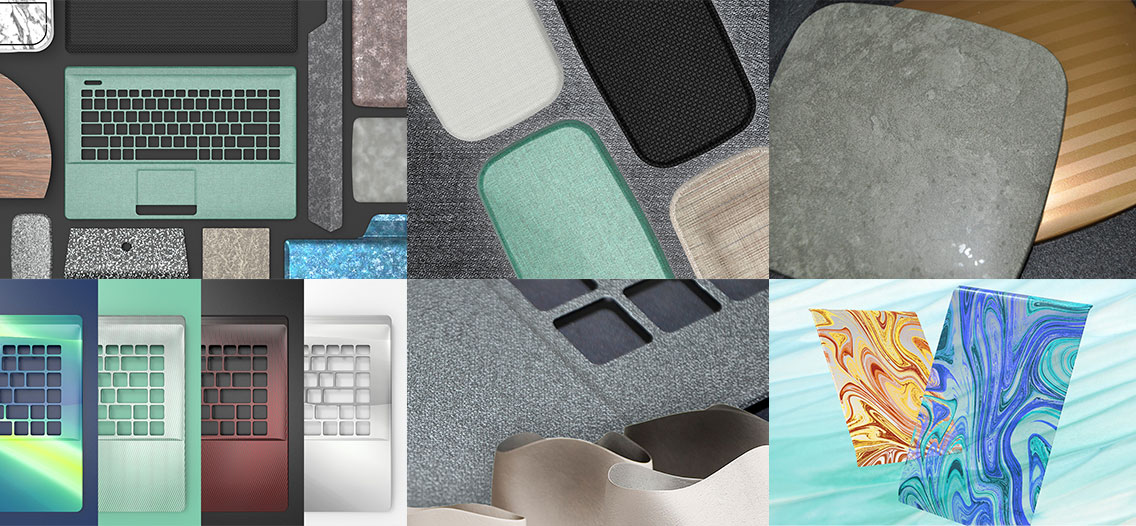

In the world of production, the art of in-mold decorations stands as a pivotal element of item layout and manufacturing. In-Mold Decorations. By diving right into the approaches, fads, and best methods that underpin successful in-mold design processes, companies can unlock a realm of opportunities that not only elevate the aesthetic appeal of their items but likewise improve production effectiveness and reinforce consumer engagement.

Product Selection

Material option is an important facet of grasping in-mold designs, as it directly influences the high quality and resilience of the last product. When picking products for in-mold decorations, it is vital to think about elements such as compatibility with the molding process, the desired visual result, and the environmental conditions the item will face. Thermoplastic materials like polycarbonate, polypropylene, and abdominal are commonly used for in-mold decors as a result of their adaptability and ability to attain complex styles. These materials supply superb moldability, allowing manufacturers to develop complicated shapes and patterns with precision.

In addition, products with high warmth resistance are preferred for in-mold decors, particularly for items that will be subjected to raised temperatures during their lifecycle. By carefully selecting the appropriate material for in-mold decors, manufacturers can enhance the overall high quality and resilience of their products, meeting the assumptions of both customers and end-users - In-Mold Decorations.

Style Innovation

A vital consider progressing the field of in-mold decorations is the continuous exploration and implementation of design innovation strategies. Layout advancement plays a vital duty in improving the aesthetic allure, capability, and total high quality of products manufactured utilizing in-mold decoration procedures. By integrating innovative layout components, manufacturers can distinguish their products in the market, bring in consumers, and remain in advance of competitors.

Among the crucial aspects of layout technology in in-mold designs is the integration of detailed patterns, structures, and graphics that were previously testing to accomplish with traditional design methods. Advanced modern technologies such as 3D printing and digital design devices allow designers to produce complex and in-depth designs that can be flawlessly moved onto molded components. Additionally, the usage of lively colors, metal surfaces, and unique effects like gloss or matte appearances can even more boost the visual charm of in-mold decorated products.

In addition, design advancement extends beyond aesthetics to include practical enhancements such as ergonomic forms, integrated functions, and customizable elements that satisfy specific user needs. By accepting layout innovation, producers can unlock new possibilities for item, customization, and creative thinking differentiation in the competitive landscape of in-mold designs.

Manufacturing Performance

Effective manufacturing procedures are vital for equating the cutting-edge styles established in the area of in-mold decorations right into top check over here quality finished items that fulfill market demands and customer assumptions. In the realm of in-mold decors, manufacturing efficiency incorporates different crucial elements that add to the general success of the manufacturing procedure.

Automation not only speeds up the manufacturing procedure yet additionally boosts precision and repeatability, leading to a more consistent and high-quality end item. Generally, an alternative strategy to manufacturing performance is paramount in making the most of the capacity of in-mold design methods and accomplishing ideal results in the competitive market landscape.

High Quality Control Steps

What are the essential techniques for guaranteeing rigorous quality assurance actions in the world of in-mold designs? Quality control steps are critical in in-mold decor procedures to make sure the manufacturing of premium and perfect finished items. One critical approach is the application of extensive inspection methods at every phase of the production process. This involves performing extensive visual inspections, dimensional checks, and shade uniformity analyses to determine any defects or incongruities beforehand.

Making use of sophisticated modern technologies such as automatic examination systems can also boost the quality control procedure by providing precise and reliable data for evaluation. These systems can spot flaws that might be missed by hands-on examinations, thereby improving general product high quality and consistency.

Routine training and growth programs for employees involved in the in-mold design procedure can also add to maintaining premium criteria. By educating staff on best practices, high quality assumptions, and the relevance of attention to detail, business can promote a society of high quality consciousness throughout the company.

Customer Appeal

To enhance the bankability of in-mold decor products, understanding and providing to consumer preferences play discover here a vital duty in identifying their appeal and success. Supplying customization alternatives such as individualized designs, shade variations, and textural components can substantially enhance the allure of in-mold decoration items.

Verdict

In-mold designs provide a reliable and functional method to improve product visual appeals. Mastering in-mold designs requires an all natural technique that thinks about all aspects of the production procedure to guarantee success.

In the realm of manufacturing, the art of in-mold decors stands as an essential element of item style and production. Layout advancement plays a critical function in enhancing the visual charm, functionality, and total high quality of items produced utilizing in-mold design procedures.One of the crucial aspects of style development in in-mold decors is the combination of intricate patterns, appearances, and graphics that were previously testing to achieve with typical design approaches.Effective manufacturing procedures are necessary for translating the cutting-edge designs created in the field of in-mold designs right into premium finished products that meet market demands and customer expectations. Supplying personalization options such as individualized designs, color variants, and textural elements can check my source substantially boost the appeal of in-mold design items.

Report this page